Application Range of Jwell's PP Sheet Extrusion Line

Jwell's PP sheet extrusion line is primarily used for producing Polypropylene (PP) brightness sheets. Due to its excellent transparency, chemical resistance, toughness, and recyclability, it is widely used in food packaging, medical supplies packaging, electronic product protection, printing substrates, and other fields.

Basic Components and Workflow of Jwell's PP Sheet Extrusion Line

Raw Material Preparation

First, dry PP resin pellets are used as raw materials. These materials must undergo rigorous drying treatment to remove moisture, preventing bubble formation during processing, which could affect the sheet's transparency and quality.

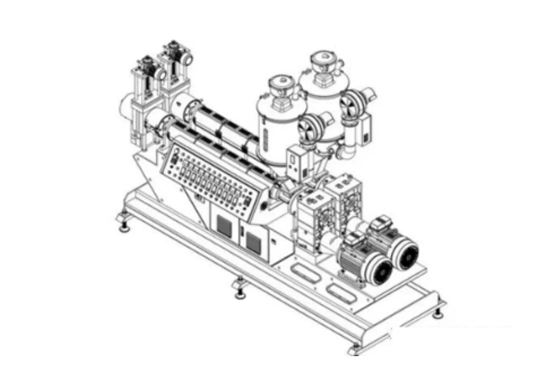

Extruder

The mixed material is fed into a single-screw or twin-screw extruder through a feeding system. The extruder melts the pellets into a uniform melt through heating and the shear, plasticizing, and conveying sections of the screw.

Filtration System

To ensure the transparency and purity of the sheet, the melt passes through a precise filter after extrusion to remove any potential impurities, such as unmelted resin pellets or foreign substances.

Metering Pump

The filtered melt enters the metering pump, which precisely controls the melt flow and synchronizes with the main machine, effectively stabilizing the delivery of the molten material to the sheet forming die head, playing a crucial role in adjusting the sheet's thickness.

Molds and Dies

The molten PP material exiting the extruder passes through specially designed molds and dies to form a sheet of the desired thickness and flatness, controlling the product's width. For sheets, the design of the molds and dies is particularly critical, ensuring even material flow without bubble formation to meet brightness requirements.

Cooling and Shaping System

The hot melt sheet from the die head immediately enters the calender for rapid cooling and shaping, adjusting the sheet's thickness and width. The calender controls the roller temperature using water cooling (or a chiller). Due to the significant shrinkage of PP, it must be completely cooled before winding to eliminate internal stress, ensuring that the product meets quality standards and does not shrink after winding and storage.

Haul-Off and Edge Trimming Device

The cooled and shaped sheet passes through an edge trimming device, where it is cut to the required dimensions. The required sheet width is adjusted, and imperfect edges on both sides are trimmed. The haul-off device and calender operate synchronously, effectively controlling sheet production, speed, and tension to maintain sheet flatness and thickness uniformity.

Winding System

Lastly, the trimmed sheet is wound onto a reel. The take-up reel, controlled by a servo motor, maintains consistent tension for uniform winding, ensuring that the inner and outer layers of the roll have the same tension, preventing the inner layers from being too tight and the outer layers too loose. This facilitates subsequent packaging, storage, and transportation.

Final step

If producing sheeting for printed packaging, a slicer needs to be added at the end. During production, a laminating device should be included to laminate the upper and lower sides of the sheet before slicing (the film can be manually peeled off) to protect the sheet during transport and prevent surface damage.

Finally, in the entire production process of Jwell's PP sheet extrusion line, temperature control, material ratio, cooling efficiency, and mechanical precision are critical factors influencing the extrusion line's performance. Additionally, to meet various application needs, the production line may integrate an additive feeding system to add anti-static agents, lubricants, or other modifiers to improve sheet performance.

EN

EN