Application of Thermoplastic Elastomer

Thermoplastic elastomers (TPE) are widely used in many fields due to their unique physical and chemical properties. The following are some of the main areas of application:

Automotive Industry:TPE is used to manufacture interior and exterior trim parts of automobiles, such as sealing strips, bumpers, dashboards, door panels, lights, etc.

Medical :Due to its biocompatibility and non-toxicity, TPE is used in the manufacture of medical instruments and equipment such as infusion tubes, blood bags, medical gloves, etc.

Consumer Products:TPE is used in the manufacture of various everyday items such as sports equipment, toys, footwear, furniture, etc.

Electronics and electrical appliances TPE is used to manufacture wires and cables, housings and gaskets of electronic equipment, etc.

Packaging industry TPE can be used to manufacture flexible packaging materials, seals and caps, etc.

Thermoplastic Elastomer Formulation

The formula of TPE can be adjusted according to the required performance, and the following are some basic formula compositions:

Basic polymer | SBS,PP,TPU,TPEE Etc |

|

Plasticizer | Phthalate esters,Aliphatic dibasic acid esters | Used to adjust the hardness and flexibility of TPE |

Filler | Calcium carbonate,talcum powder, etc | Improve the processing performance of TPE and reduce costs |

Stabilizers | Antioxidants, UV absorbers, etc | Improve the aging resistance of TPE |

Colorant | Inorganic pigment or organic dye | Adjust the color of TPE |

Other additives | Flame retardants, antistatic agents, lubricants, etc | Added according to specific application requirements |

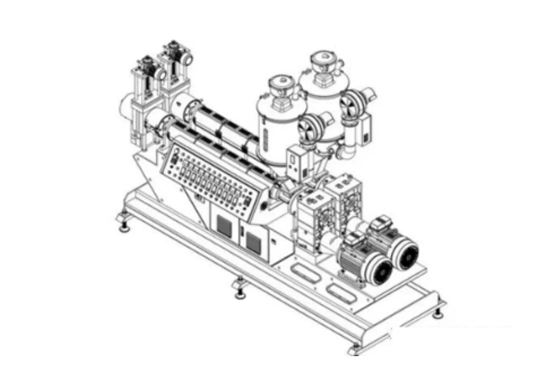

Key points of TPE Compounding MachineProcess

1. Mixing: The production of TPE first requires the uniform mixing of various raw materials, which is usually done in a twin-screw extruder.

2. Dynamic vulcanization : For TPE requiring vulcanization, such as TPO, dynamic vulcanization is a key step, which is carried out under the action of high temperature and shear force.

3. Temperature control: Temperature control is essential throughout the process to ensure material flowability and uniformity of reaction.

4. Exhaust: During the mixing process, it is necessary to exclude air and volatile substances from the material to prevent bubbles and degradation of the material.

5. Shear force : Proper shear force is helpful to the mixing of raw materials and the progress of reaction.

6. Cooling: The processed material needs to be cooled rapidly to fix its shape and properties.

7. Post-treatment: As required, TPE products may require post-treatment, such as annealing, surface treatment, etc., to improve their performance.

Specific formulations and processes may vary depending on specific product requirements and application areas.

EN

EN