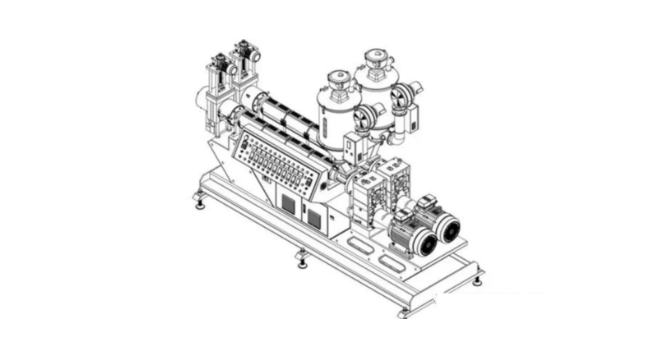

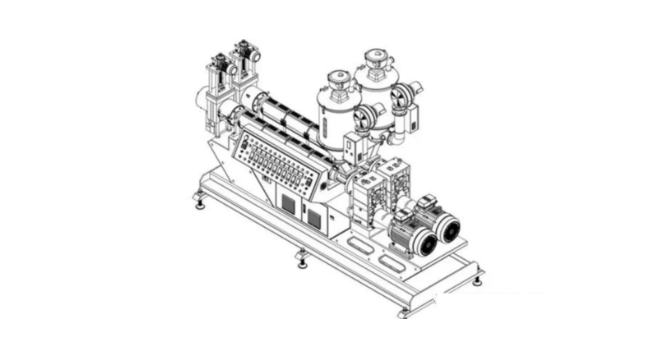

With the production and manufacturing process of the twin-screw extruder getting better and better, it not only has to carry out tasks such as feeding plasticization, but also has some requirements such as dehydration and drying, in order to better meet the different needs of users, the twin-screw extruder must continue to improve its work efficiency, and also need to find ways to improve the quality of the products produced, so how should we do it?

Here are the specific ways to improve production efficiency and product quality!

1. How to improve the work efficiency of the twin-screw extruder:

Improving work efficiency is one of the most important goals in the development, design and development of the new co-directional rotary twin screw extruder, which can also be achieved by increasing the screw speed, increasing the plasticizing and mixing level, etc. At the same screw speed, expanding the depth of the screw groove can greatly increase the conveying capacity. In contrast, the plasticizing and mixing levels of the screw must also be expanded, which requires the screw to be able to withstand higher torques.

At a high screw speed, the residence time of the material in the extruder is reduced, which may make the material plasticized, melted, and mixed not very sufficient.

Therefore, the screw length must be increased appropriately, which in turn inevitably results in the twin screw extruder machine actually carrying an increase in torque and power.

Expanding the free volume of the screw groove is also a crucial factor. In the feeding section and devolatilization section, it is very necessary for the threaded element to have a large free volume, for bulk density materials, expanding the free volume of the feeding section and the filling degree of the material in the screw groove can greatly improve the processing capacity of the extruder.

To increase the torque and speed, the deceleration distribution box needs to be carefully designed. In order to greatly improve the torque index of the equipment, it will put forward a higher need for the design and manufacturing level of the transmission box.

The higher the torque, the higher the design, manufacturing accuracy, material strength and heat treatment of gears, output shafts, bearings and other parts in the gearbox, and the higher the design, production and manufacturing accuracy of the screw mandrel, threaded elements and kneading discs.

Because it is necessary to expand the free volume of the threaded element, the center distance between the two screws will be reduced under the condition that the outer diameter of the screw remains the same, which will make the problem that the installation space of the proportioned gear and thrust bearing is not very prominent more prominent.

2. How to improve the product quality of the twin-screw extruder:

In order to achieve high product quality, the design of the plasticizing system, the core component of the extruder, is of great importance.

The plasticizing system mainly includes a screw and a barrel, and in order to meet the requirements of various types of production and processing, the screw and barrel are generally designed as a building block combination structure. According to the function of each stage, the screw can be divided into charging section, plasticizing section, mixing section, exhaust section and extrusion section. These sections have different roles in the extrusion process, their structures are different, and the corresponding geometric parameters of the screw elements are also different, so how to determine the geometric parameters of the threaded elements has become the key to the design of the plasticizing system.

For the co-rotating twin screws, there is a certain correlation between the middle diameter ratio (that is, the ratio of the center distance of the two screws to the radius of the screw), the number of thread heads and the top angle of the thread, and the design scheme cannot be arbitrary, otherwise there will be interference between the two screws.

In order to solve this problem, the author obtains the theoretical end face curve of the screw according to the motion trajectory of the two screws, and uses the three-dimensional solid modeling effect of the large-scale computer-aided design scheme (CAD) software to compile the geometric modeling program of the twin screws, realizes the three-dimensional solid graphic display of the twin screws, obtains the geometric parameters of various types of self-cleaning threaded elements, and tests the meshing of the two screws.

In addition, the integration of project practice, with the help of the computer, completed the three-dimensional solid modeling of the twin screw with gaps, which can be used to check whether the gaps of the two screws are uniform, so that the material has no dead angle in the screw movement, that is, to ensure that the screw has a strong self-cleaning ability, can effectively prevent the material from staying in the machine for too long and degrading, which undoubtedly provides a good means of production and processing for the production and manufacture of high-grade and high-quality plastic products.

EN

EN