DYSS Series of Single Shaft Shredder

DYSS Series type is designed to meet the small quantity waste recycling requirements, such as blocks, pipes and woven bags, various used cables, wood, waste paper and electronic waste etc.

| Model | Rotor Dia (mm) | Drive Power (kw) | Rotor Blades (pcs) | Fixed Blade (pcs) | Crushing chamer size max. (mm) |

| DYSS-600 | Φ200 | 18.5 | 23 | 4 | 600x500 |

| DYSS-800 | Φ400 | 37 | 39 | 6 | 800x800 |

DYSSJ Series of Single Shaft Shredder

DYSSJ series is universal type, standard seratted pushing feeder is equipped to the DYSSSJ shredder, which makes it easier to shred big blocks pallet and wood.

| Model | Rotor Dia (mm) | Drive Power (kw) | Rotor Blades (pcs) | Fixed Blade (pcs) | Crushing chamer size max. (mm) |

| DYSS-850 | Φ435 | 37 | 60 | 3x2 | 700x730 |

| DYSS-1500 | Φ505 | 37 | 102 | 5x2 | 800x1200 |

DYSSJ series is designed for shredding PE, PP and PVC pipes with a diameter of 1600mm. Pipes with a length of 3-6m can be directly crushed without splitting.

| Model | Rotor Dia (mm) | Drive Power (kw) | Shreddable pipe Dia Max (mm) | Output (kg/h) |

| DYSSG-630 | Φ848 | 2X30 | 630 | 800-1000 |

| DYSSG-800 | Φ1028 | 2X37 | 800 | 1000-1200 |

| DYSSG-1000 | Φ1258 | 2X45 | 1000 | 1200-1500 |

| DYSSG-1200 | Φ1478 | 2X55 | 1200 | 1500-2000 |

| DYSSG-1600 | Φ1968 | 2X110 | 1600 | 1800-2500 |

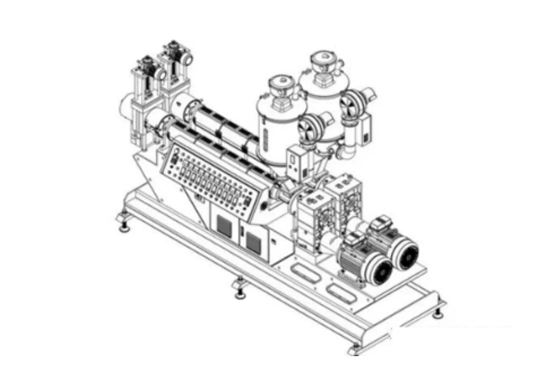

DYTSS Series of Two Shaft Shredder

This series of shredder is particularly suitable for the crushing of large-sized plastic material. After being shredded, the bulk density of the material can be increased, thereby reducing transportation costs. In addition, the material can be further processed after shredding, such as material separation,washing and pelletizing etc.

| Model | Rotor Dia (mm) | Driver Power (kw) | Rotor Blade (pcs) | Blade thickness (mm) | Crushing chamber size max (mm) |

| DYTSS-32100 | Φ430 | 22x2 | 26 | 40 | 1000x800 |

| DYTSS-40130 | Φ514 | 37x2 | 26 | 50 | 1300x950 |

| DYTSS-50180 | Φ615 | 55x2 | 36 | 50 | 1800x1200 |

DYFSS Series of Four-shaft shredder

Four-shaft series shredders are made of multifunction and versatility. Shredders of this series are applicable to shred plastic barrels, plastic frames, woven bags, circuit board and paper box etc., and have advantages of controllable discharging size, high efficiency, low rotate speed and low noise.

| Model | Motor Power (kw) | Blade Thickness (mm) | Main blade dia (mm) | Main blade (pcs.) | Crushing chamer size max. (mm) |

| DYFSS-9080 | 2X18.5 | 290 | Φ25 | 30 | 900*800 |

| DYFSS-100120 | 2X22 | 320 | Φ40 | 32 | 1000*1200 |

| DYFSS-130140 | 2X15+2X30 | 430 | Φ50 | 28 | 1300*1400 |

EN

EN