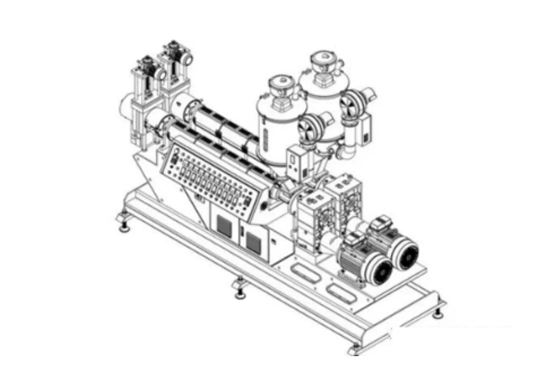

Overview of Masterbatch Extrusion Line

Color masterbatch, also known as color concentrate, is a special coloring agfor polymer materials, composed of pigments or dyes, carriers, and additives,forming a pigment concentrate with higher coloring strength than the pigmentthemselves. There are various methods for classifying color masterbatches, which can be categorized according to the carrier, color, or function.

Classification of color masterbatches:

- By carrier: PE masterbatch, PP masterbatch, ABS masterbatch, etc.

- By color: colored masterbatches, black masterbatches, white masterbatches, etc.

- By function: coloring masterbatches, anti-aging masterbatches, anti-static masterbatches, antibacterial masterbatches,flame-retardant masterbatches, and other functional color masterbatches.

Formula of Masterbatch Extrusion Line

Color masterbatch is generally added with various organic pigments, the highest proportion is 40%;

Black masterbatch is generally added carbon black, the highest proportion is 55%;

White masterbatch is generally added TiO2, the highest proportion is 75%.

Process of Masterbatch Extrusion Line

Color masterbatch production can be divided into premixing method and multiple feeding method according to the process characteristics.

Premixing method is relatively simple with high speed mixer.

Multi-feeding method usually uses loss-in-weight feeders for precise raw material feeding,

To improve the quality, all ingredients are generally premixed with kneader to get better dispersion when producing white and black masterbatches.

Advantage of Masterbatch Extrusion Line

JWELL twin screw extruder adopts narrow gap design for color masterbatch to improve shearing and dispersing ability and ensure compounding quality

To improve the quality, all ingredients are generally premixed with kneader to get better dispersion when producing white and black masterbatches.

EN

EN