Overview of Masterbatch Extruder

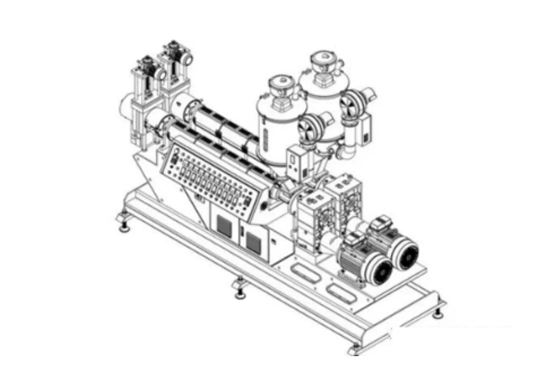

High filler extrusion processing is the evenly compounding and dispersion of high percentage inorganic powder into carrier resins. During this process, the carrier should not suffer over shear to maintain its physical properties. At the same time higher output and lower wear-off of machine parts brings better cost effectiveness.

High Filler - Types of Masterbatch Extruder

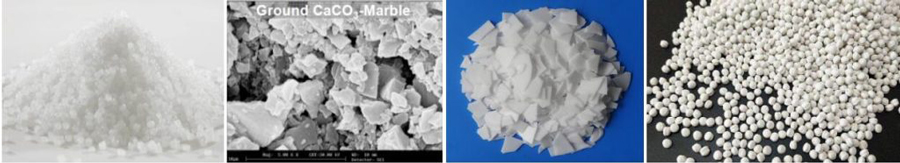

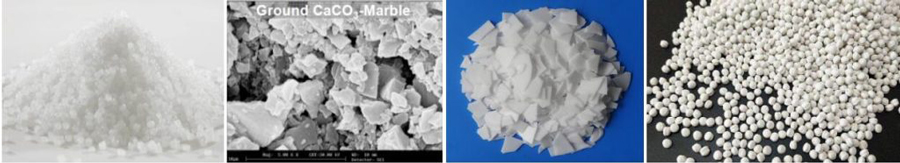

PP Calcium carbonate High Filler masterbatch

PE calcium carbonate High Filler masterbatch

Talcum powder High Filler masterbatch

Transparent High Filler masterbatch

Key Technologies of Masterbatch Extruder

1. Reasonable formula design and lubrication of raw materials, which means proper carrier MFI and percentage, uniform powder size and suitable surface treatment. The typical recipe is PE/PP+85%CaCO3+lubricant to make CaCO3 filled masterbatch. Coupling agents are generally added to get better combination of CaCO3 and carrier.

Premixing based on high mixer

premix all the ingredients in high speed mixer to a certain time or temperature, and then feed mixed material into twin screw extruder for further compounding. During the premixing process, the lubricant has a strong infiltration effect on the powder, and large volume of moisture is naturally removed through high temperature, which makes it easier for feeding and brings higher output. It is also suggested to have a cooling mixer after high speed mixer to avoid the degradation of resin by high temperature stack handling.

Premix based on kneader

mix all the ingredients in the kneader for a certain time, and then feed the bulk material into twin screw extruder with force conical feeder for further compounding. Compared with high speed mixer, pre-mixing of kneader has plasticized the raw materials, which requires less for the compounding ability of extruder and helps to increase the output. Sufficient pre-mixing and lower degradation of raw material makes it applicable for film filler masterbatches, stone paper filler masterbatches etc, in which application good dispersion and high physical properties are required.

EN

EN