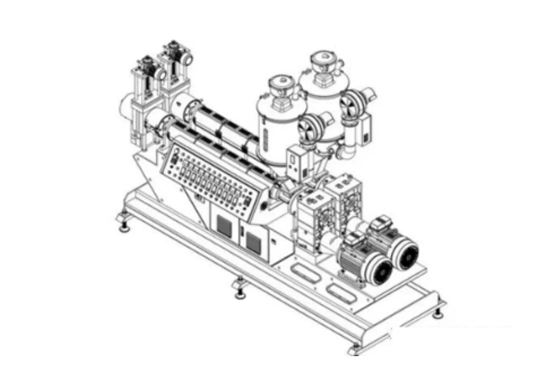

Experience the pinnacle of efficiency and versatility in polymer compounding with JWELL Compounding Extrusion solutions. JWELL range includes engineering plastic compounding machines, PET recycling twin screw extruders, and high-capacity extruders for petrochemical applications. Engineered with precision and innovation, JWELL extruders ensure uniform dispersion of additives, efficient blending of materials, and consistent quality in every compound. From enhancing the performance of engineering plastics to recycling PET materials and producing high-volume compounds for petrochemical industries, JWELL Compounding Extrusion technology meets the diverse needs of modern manufacturing.

Engineering Excellence: Innovations in Plastic Compounding Technology

Engineering plastics are vital materials used in a wide range of industries, from automotive to electronics, demanding superior performance and durability. JWELL Engineering Plastic Compounding Machines are designed to meet these stringent requirements, offering precise control over material properties and additives. By blending polymers with reinforcements, fillers, and additives, our extrusion technology enhances mechanical strength, thermal stability, and flame retardancy of engineering plastics. Whether it's creating lightweight components for automotive applications or high-temperature-resistant parts for electronics, JWELL compounding extruder solutions enable manufacturers to achieve excellence in product performance and reliability.

Sustainable Solutions with PET Recycling Extrusion

With the growing emphasis on environmental sustainability, recycling PET materials has become a priority for many industries, particularly in packaging and textiles. JWELL PET Recycling Twin Screw Extruders play a crucial role in this endeavor, offering efficient and cost-effective solutions for transforming PET waste into high-quality recycled pellets. By removing impurities, decontaminating the material, and achieving precise melt characteristics, JWELL extrusion technology ensures the production of recycled PET materials that meet or exceed virgin resin quality standards. Explore how JWELL PET recycling extrusion solutions enable manufacturers to close the loop on plastic waste, reduce dependency on virgin materials, and contribute to a circular economy.

EN

EN