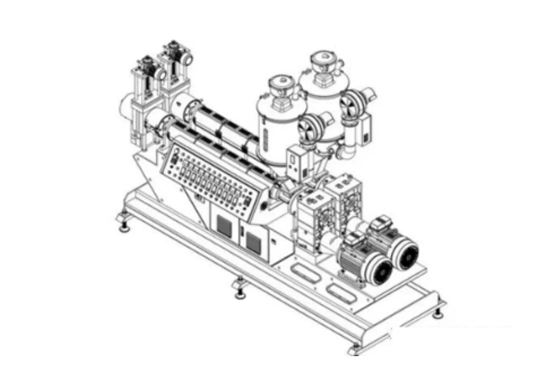

The integration of sheet extruders in the building material industry has revolutionized construction practices by offering a sustainable, cost-effective, and versatile solution for producing high-quality building materials. From durable roofing sheets and weather-resistant wall cladding to innovative flooring options and insulation panels, sheet extruders enable the creation of a wide array of products that meet the diverse needs of modern construction. These extruded plastic materials produced by Jwell plastic extrusion technology not only enhance the aesthetic appeal of buildings but also contribute to energy efficiency and longevity, marking a significant step forward in sustainable building practices.

The Development of Sheet Extruder Used in Building Material Industry

The evolution of sheet extruders in the building material industry marks a transformative journey towards innovation and sustainability. Initially designed for producing basic plastic sheets, modern extruders now craft a diverse array of high-performance, eco-friendly materials for construction. Technological advancements have expanded their capabilities, enabling the production of complex, multi-layered products from recycled and composite materials. This progress reflects the industry’s shift towards energy efficiency, waste reduction, and customized solutions, positioning sheet extruders as pivotal in the development of next-generation building materials that meet the demands of contemporary construction practices.

The Role of Sheet Extruders in Modern Architecture

Sheet extruders play a pivotal role in modern architecture, enabling the creation of innovative, sustainable, and versatile building materials. These advanced machines produce high-quality extruded sheets used in a myriad of applications, from striking façades to energy-efficient roofing and durable flooring. By facilitating the use of recycled materials and offering unparalleled design flexibility, sheet extruders empower architects to push the boundaries of creativity while adhering to green building principles. The result is a new era of architectural designs that are not only aesthetically pleasing but also environmentally responsible and highly functional.

EN

EN