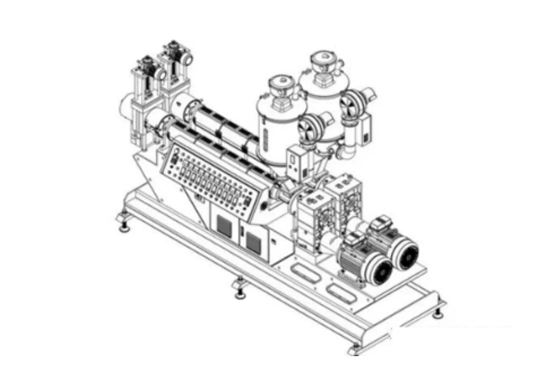

The Profile Extrusion Machine and Plastic Recycling Machine are cornerstone technologies in the plastics industry, each serving a critical role in sustainable manufacturing. Profile extrusion machines specialize in creating complex cross-sectional profiles, such as window frames, tubing, and seals, offering precision and versatility in shaping various polymers. On the other hand, plastic recycling machines are pivotal in the circular economy, transforming waste plastic into reusable raw materials. These machines grind, wash, and reprocess discarded plastics into high-quality pellets, reducing environmental impact and promoting resource efficiency. Together, they embody the industry’s commitment to innovation, sustainability, and the responsible use of plastic materials.

Outstanding Features of Profile Extrusion Machine and Plastic Recycling Machine

The Profile Extrusion Machine boasts remarkable precision in manufacturing complex profiles, with capabilities for customizing shapes and sizes to meet diverse industry needs, from construction to automotive. Its advanced control systems ensure consistent quality and efficiency in production. Meanwhile, the Plastic Recycling Machine stands out for its contribution to sustainability, featuring innovative technologies that efficiently process and convert waste plastics into high-quality recycled pellets. This machine supports a wide range of plastic types, emphasizing versatility and environmental responsibility. Both machines exemplify the fusion of technological advancement and eco-friendly practices, driving forward the plastics industry with efficiency, precision, and a commitment to reducing the environmental footprint.

Functions of Profile Extrusion Machine and Plastic Recycling Machine

A Profile Extrusion Machine is designed to manufacture complex cross-sectional profiles from raw plastic materials, such as PVC or polyethylene, through a continuous process involving melting, shaping, and cooling. It is widely used in producing items like window frames, pipes, and tubing. On the other hand, a Plastic Recycling Machine plays a crucial role in the circular economy by converting waste plastic materials into reusable forms. It typically involves processes such as shredding, washing, melting, and re-pelletizing discarded plastic, thus reducing environmental pollution and conserving resources by turning waste into valuable products.

EN

EN