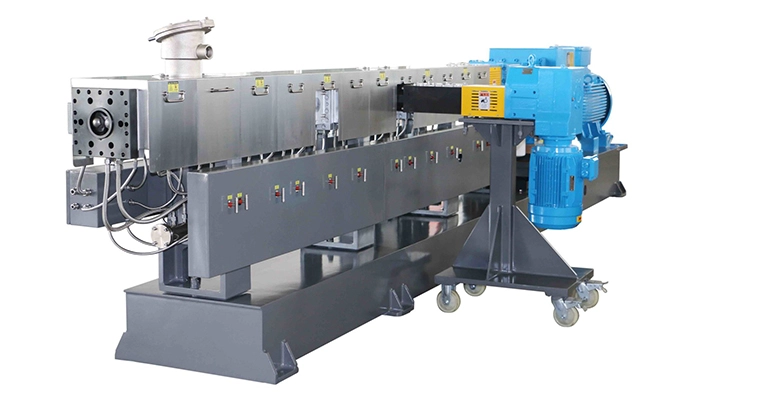

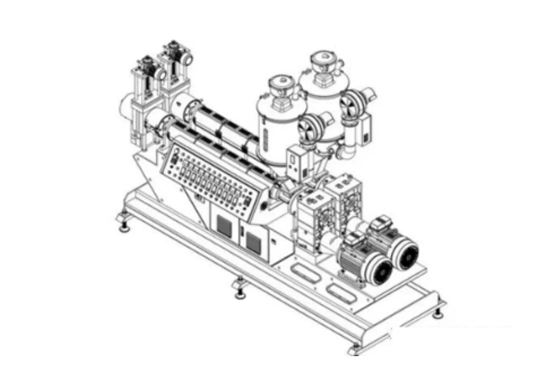

Explore the world of Twin Screw Extruders and their components with Jwell, where innovation meets precision. Our comprehensive range of extruders and accessories ensures superior performance and efficiency in various industries. From advanced screw designs to cutting-edge control systems, we offer solutions tailored to your unique requirements. Discover how Jwell's expertise in Twin Screw Extrusion technology can elevate your production processes to new heights of excellence.

Unveiling the Dynamics of Twin Screw Extruders: Driving Efficiency in Production

JWELL Twin screw extruders are designed to process a wide range of materials, including plastics, rubbers, and composites. Their adjustable screw speeds, temperatures, and feed rates allow for precise control over the extrusion process, making them suitable for various applications.

The intermeshing design of twin screws ensures thorough mixing and blending of materials, resulting in a more uniform and consistent product. This improves the overall quality of the extruded product, reducing waste and enhancing production efficiency.

Twin screw extruders feature efficient heating and cooling systems that allow for precise temperature control. This ensures that the material is processed at the optimal temperature, enhancing its flowability and reducing the likelihood of degradation or scorching.

The synchronized rotation of twin screws provides higher torque and extrusion pressure, allowing for increased output. This results in higher production rates and lower costs per unit, driving overall efficiency.

Twin screw extruders often feature modular components that can be easily replaced or modified. This flexibility allows for quick adaptation to changing production requirements, reducing downtime and enhancing production flexibility.

By reducing waste and improving material utilization, twin screw extruders contribute to environmental sustainability.

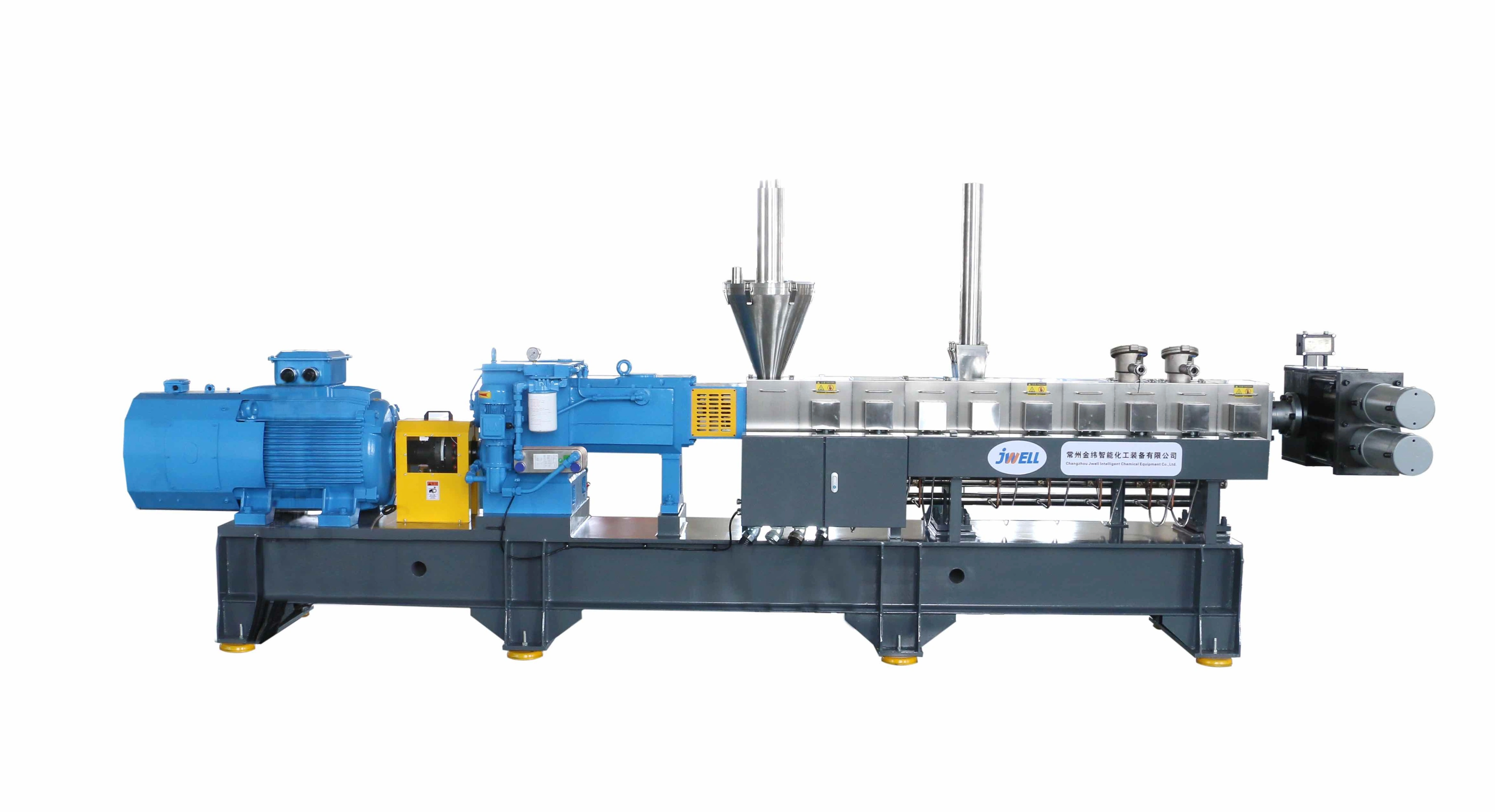

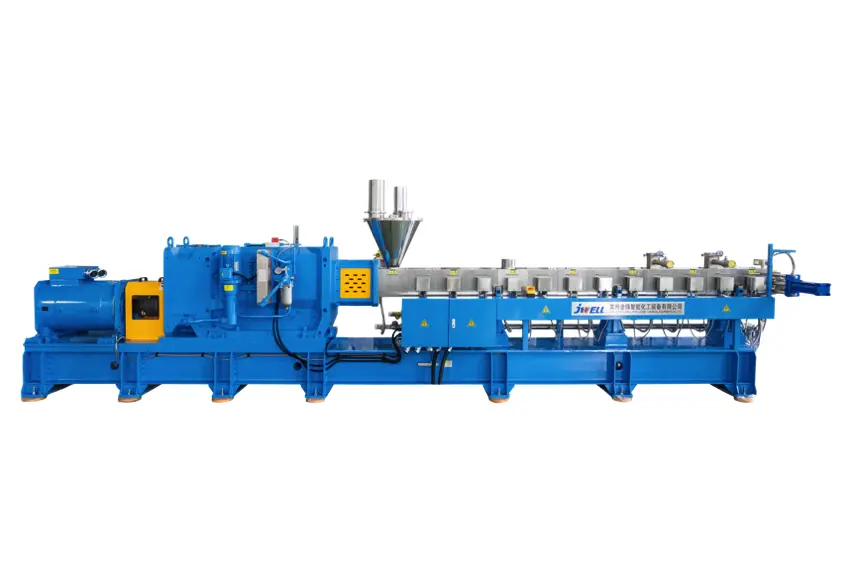

Key Components for Twin Screw Extruders

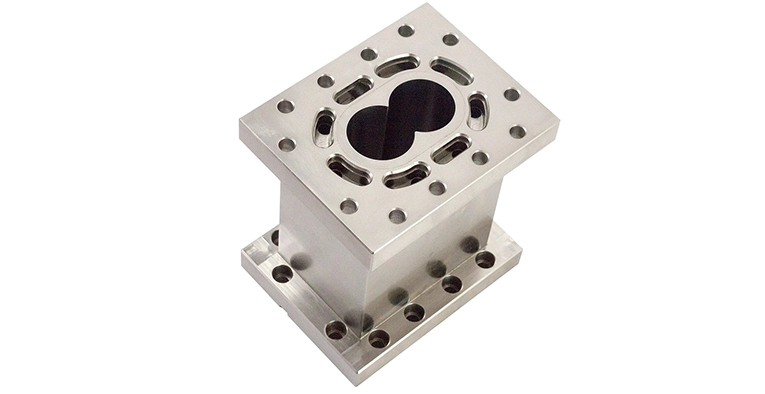

Barrels:

At the heart of every JWELL Twin Screw Extruder are its barrel segments, meticulously designed to withstand high temperatures, pressures, and abrasive materials.

Screw Elements:

The screw elements within JWELL Twin Screw Extruders are the workhorses responsible for conveying, shearing, and mixing the materials as they progress through the extrusion process.

Feeding Systems:

Efficient material feeding is crucial for maintaining consistent throughput and quality in JWELL Twin Screw Extrusion.

Heating and Cooling Systems:

Temperature control is paramount in JWELLTwin Screw Extrusion to achieve the desired rheological properties of the melt and prevent thermal degradation of the materials.

EN

EN