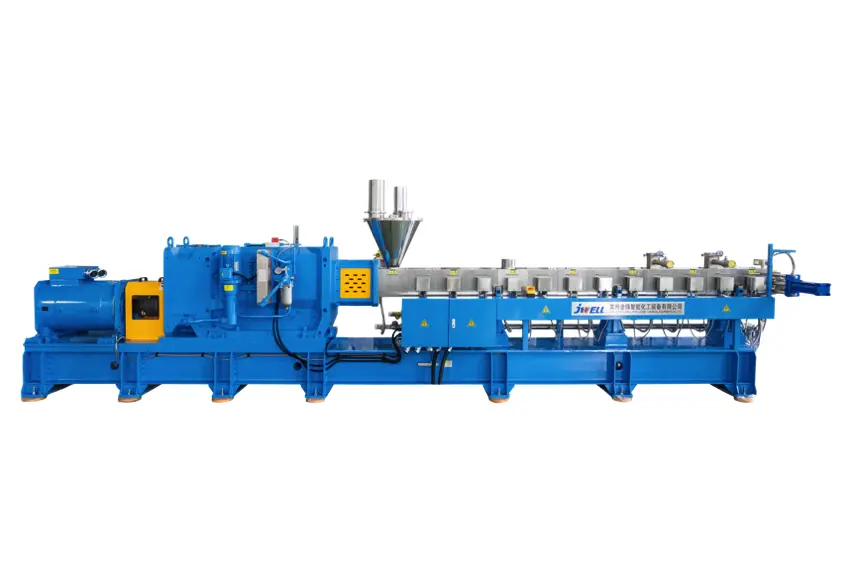

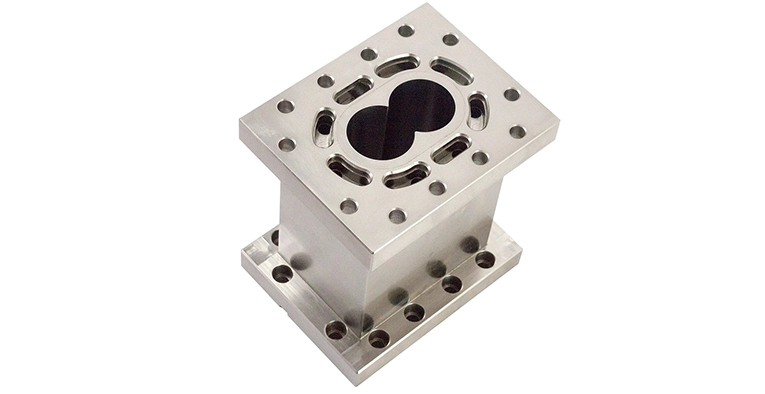

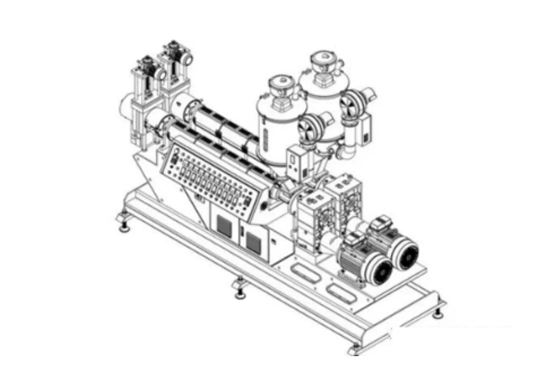

Step into the realm of advanced polymer processing with JWELL Machinery Twin Screw Extruder, a powerhouse of innovation and efficiency. Engineered to perfection, this JWELL extrusion machine offers unparalleled versatility, precision, and productivity in the production of various plastic products. From compounding and mixing to devolatilization and reactive extrusion, JWELL Twin Screw Extruder caters to diverse industrial needs with ease. Experience seamless operation and superior results with our state-of-the-art extrusion Process technology.

The Role of Twin Screw Extruders in Polymer Compounding

Polymer compounding is essential for enhancing the performance and properties of plastic materials, and our Twin Screw Extruder is at the forefront of innovation in this field. By precisely controlling mixing, dispersing additives, and incorporating fillers, our extrusion machine enables the creation of custom polymer formulations tailored to specific application requirements. Whether it's improving mechanical strength, thermal stability, or flame retardancy, manufacturers rely on our technology to unlock the full potential of polymers. Explore how our Twin Screw Extruder is driving advancements in material science, enabling the development of high-performance plastics for a wide range of industries.

From Ingredients to Finished Products: Twin Screw Extrusion in Food and Pharma

Precise Ingredient Mixing: Twin Screw Extrusion allows precise control over the mixing process, ensuring uniform distribution of ingredients. In the food industry, this means consistent flavor, texture, and nutritional content in products like snacks, cereals, and pet foods. Similarly, in pharmaceuticals, it ensures homogeneity in drug formulations, minimizing variability in dosage and efficacy.

Texture and Structure Development: For food products, Twin Screw Extrusion enables the creation of a variety of textures, from crispy snacks to chewy granola bars, by controlling parameters such as temperature, pressure, and screw configuration. In pharmaceuticals, it's used to produce controlled-release formulations, modified-release dosage forms, and oral disintegrating tablets, enhancing patient compliance and therapeutic outcomes.

Functional Ingredient Incorporation: Many functional ingredients, such as vitamins, minerals, antioxidants, and probiotics, can be easily incorporated into food and pharmaceutical formulations using Twin Screw Extrusion. This ensures even distribution and stability of these ingredients, enhancing the nutritional profile of food products and the therapeutic benefits of pharmaceuticals.

EN

EN